Liquid Handeler Reverse Engineering :

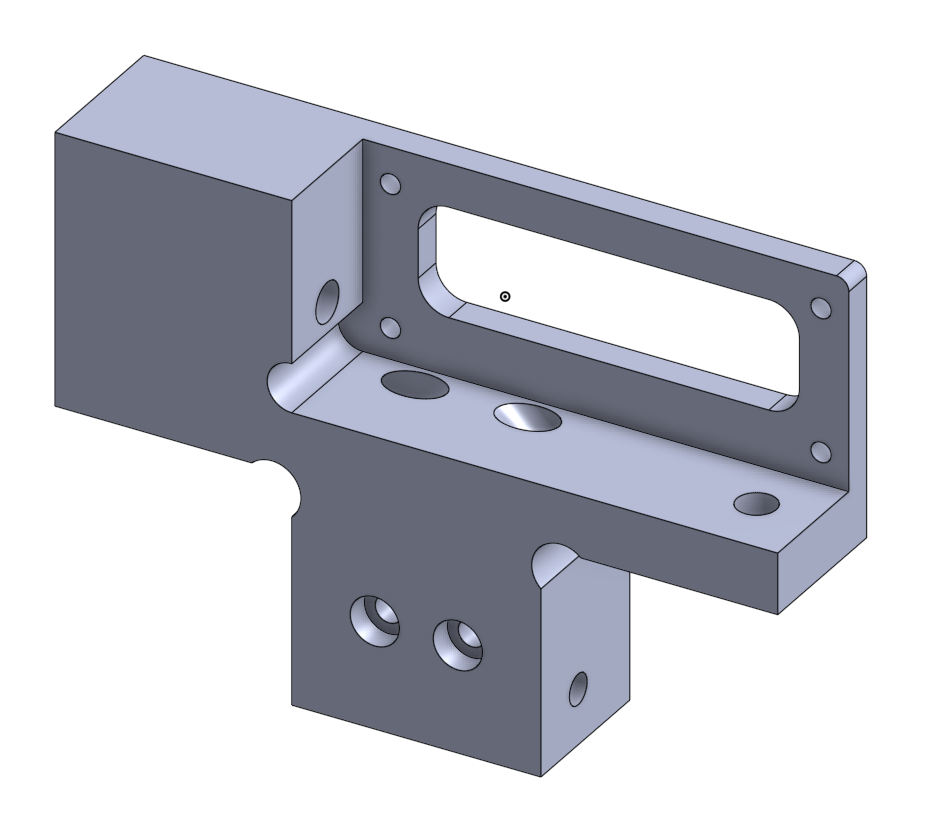

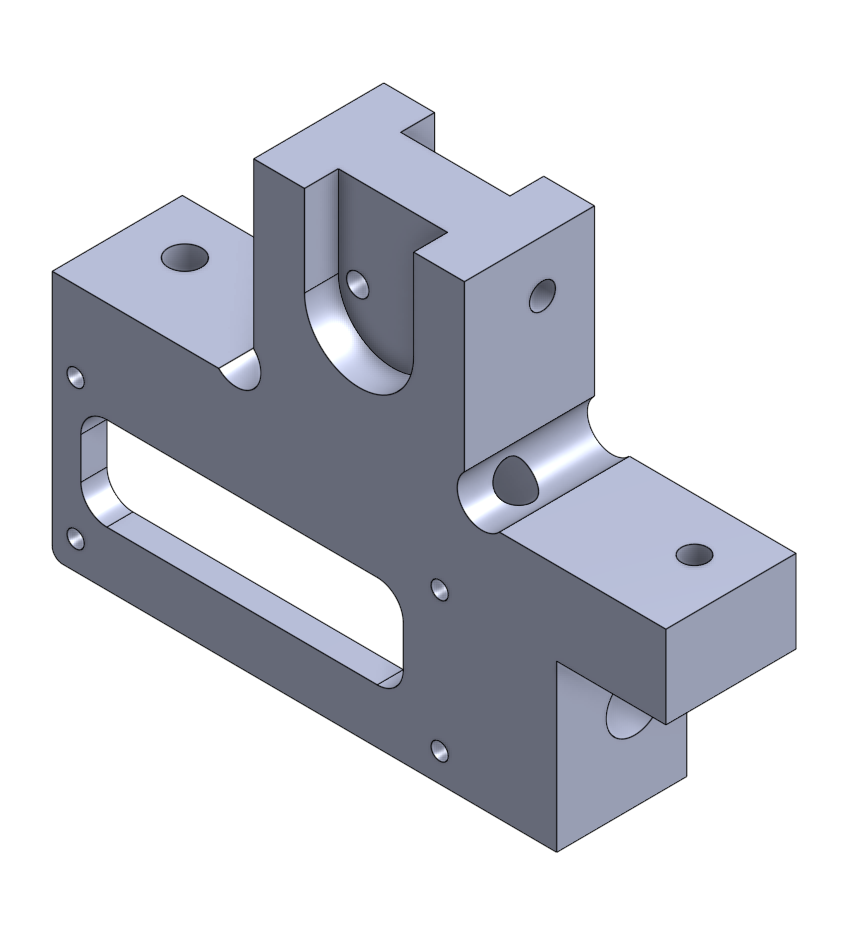

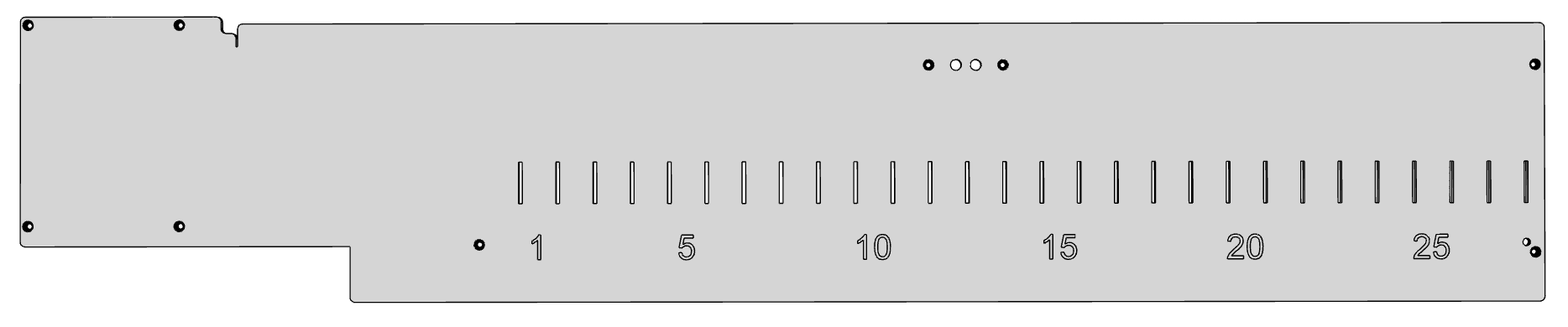

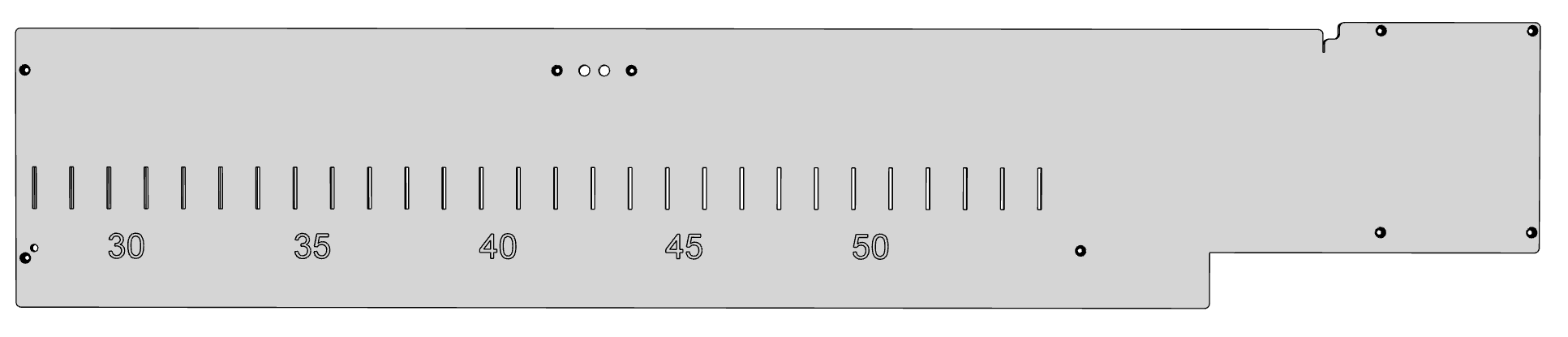

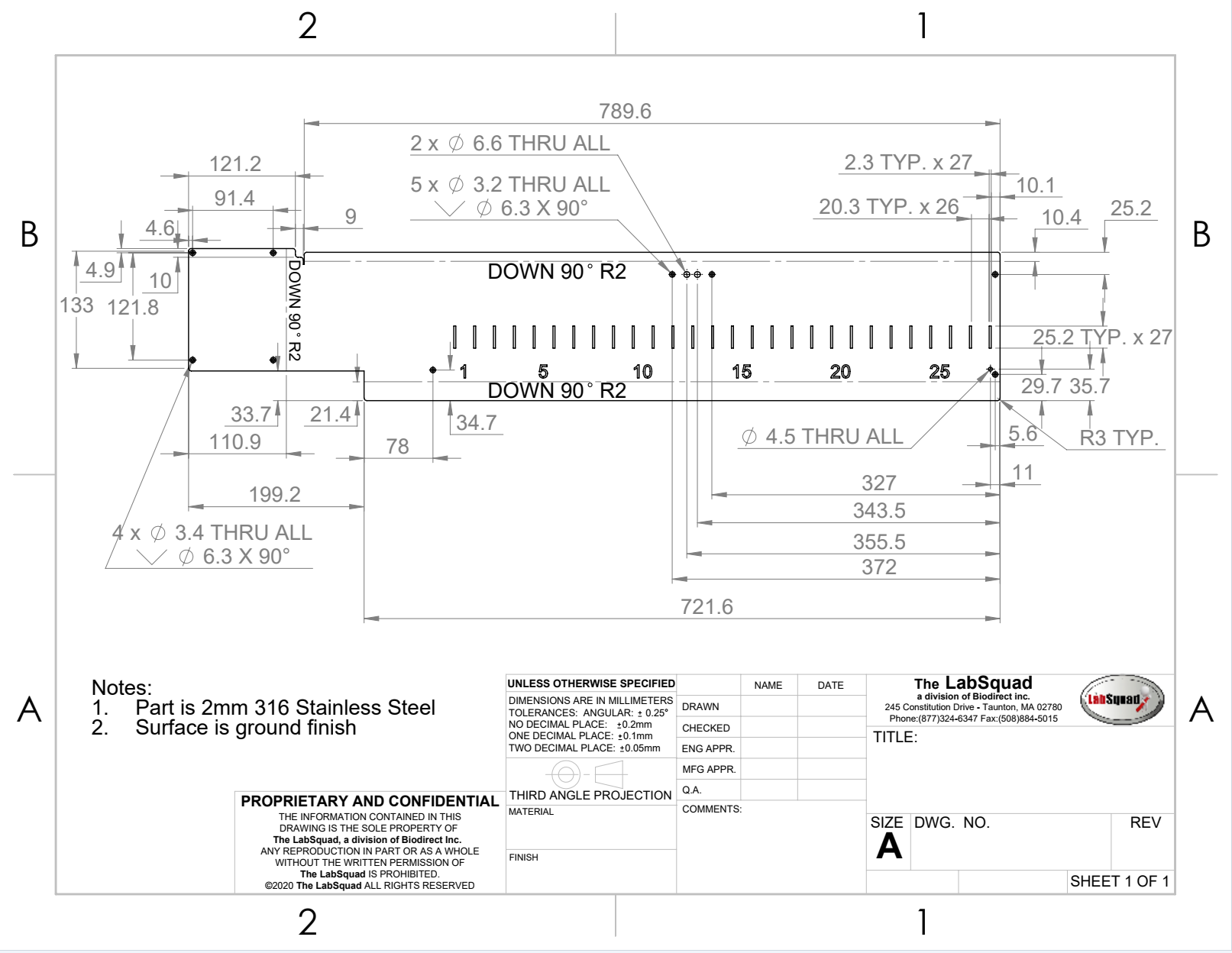

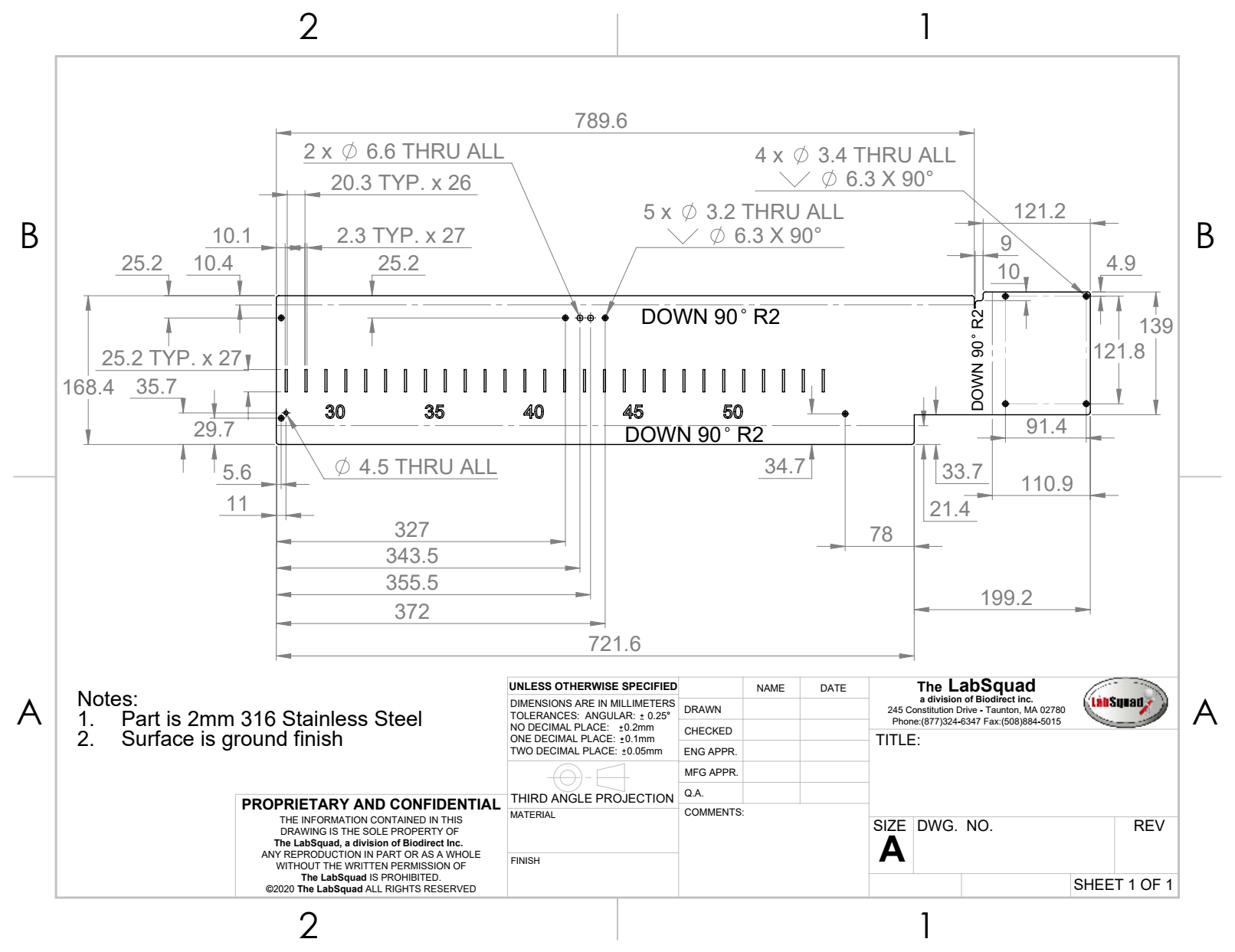

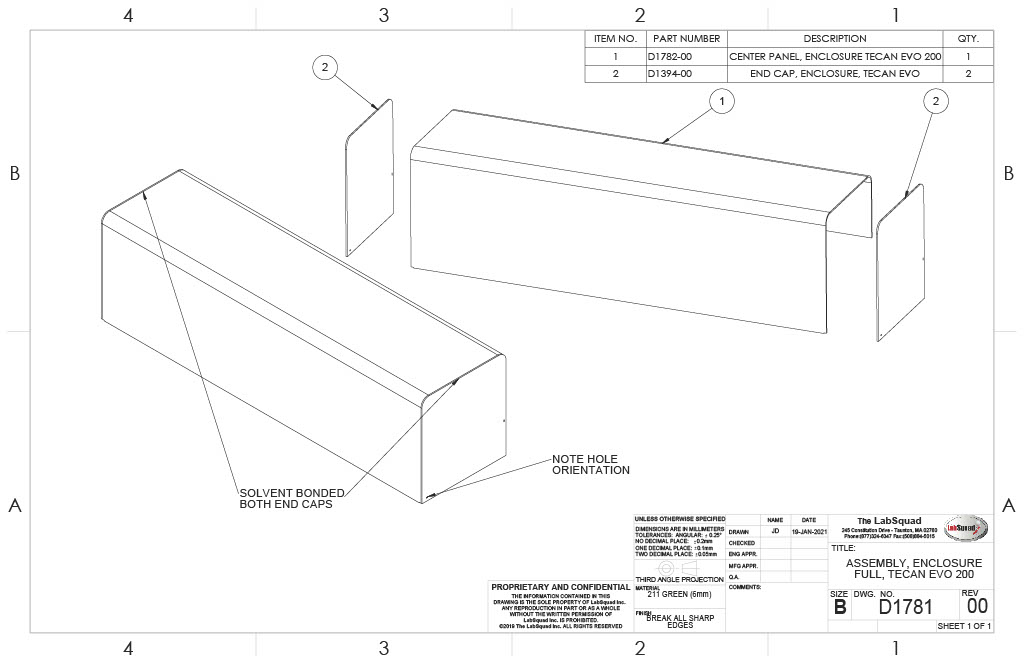

Copia Scientific is a used lab equipment reseller. They mostly deal with liquid handelers which are large automated systems used to pipette in and out of multiple vessels at rapid speeds. One common example use case from shortly before I joined was doing large batches of Covid tests. My role at Copia was reverse engineering the pieces on systems that commonly came in worn or damaged. The three example projects shown on the left are (from top to bottom) belt drive components, benchtop panels, and the enclosure placed on top of the units. I modeled all of these and then worked with local vendors to get them manufactured. On appearance parts such as the panels and enclosure this included frequent communication to find proper finish and color.

I was the third engineer at Copia, and the first with experience with electromechanical systems and 3d printing. With these conditions I had the oppurtunity to expand Copia's capabilities. I don't have any pictures to display these capabilities, but I still wanted to highlight a few. One area they had previously struggled in was sourcing motors since they were usually proprietary. In the more precise assemblies this could be circumvented by buying the generic verison of the motor and removing the gearbox from the damaged one. In more forgiving assemblies this could be solved by simply finding motors with similar dimensions and using trial and error to determine specs. Copia was using an FDM printer when I joined but had an unused Stratasys Polyjet that I helped set up. I also connected with a new vendor with an HP MultiJet that we worked with frequently for rapid high complexity parts. With the new capabilities and extra engineering time I was also involved in custom engineering work for customers. This involved reverse engineering existing racks and also making our own tweaks to optimize performance.